Innovative Solutions for the

Automotive Industry

Automotive Industry

How MatGPT can help with your automotive needs

How MatGPT can help with your automotive needs

At FEHRMANN MaterialsX, we specialize in bridging the gap between traditional materials development and cutting-edge AI technology. MatGPT, a unique synergy of AI, Simulation, and targeted experiments, is designed specifically to address your most pressing challenges. With MatGPT, you will have the power to improve your production processes, enhance material properties, and accelerate development cycles efficiently.

Lightweight materials for enhanced fuel efficiency

AI-Driven R&D: MatGPT leverages the availability of state-of-the-art know-how and internal data of lightweight alloys and composites under various conditions, speeding up the development of materials that excel in safety and performance while reducing weight.

High-performance materials for electric vehicles

AI-Optimized Manufacturing: MatGPT optimizes processing parameters for the integration of innovative materials into production lines with minimal disruption, supporting the specific needs of electric vehicle components.

Accelerated development cycles for new models

Quality Assurance Through AI: MatGPT identifies defects and deviations during material testing, thus ensuring reliability and speeding up the market readiness of new automotive models.

Adressing Challenges

Automotive applications

Automotive applications

MatGPT

Corrosion Resistance

MatGPT's capabilities in R&D and materials science help predict and mitigate corrosion processes, facilitating the creation of new, more durable aluminum alloys designed for new requirement profiles.

Weldability

Our AI-driven system optimizes welding parameters, accommodating aluminum's unique properties to improve joint integrity and performance.

Formabiltiy

By predicting the behavior of aluminum alloys under different forming processes, MatGPT enables the manufacturing of complex parts without material failure.

Sustainability & Recyclability

MatGPT accelerates the discovery of new aluminum alloys with superior strength-to-weight ratios and recyclability, crucial for producing lighter and safer vehicles with reduced carbon footprint.

real results

Our Solutions

Our Solutions

How our innovations drive your success

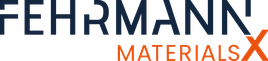

Impact Absorber Components

Impact Absorber Components

Our impact absorber components, created using a dual approach of 3D printing and die-casting, leverage the power of AlMgty® alloy, a game-changer in the field.

Silo vehicles - collars, lids, discharge funnels

Silo vehicles - collars, lids, discharge funnels

For leading national and international vehicle manufacturers like Köhler and Feldbinder, we produce seawater-resistant, pressure-tight weldable cast parts with a tensile strength of A = 12 % according to the European Pressure Equipment Directive (PED / AD2000). Only the high-stretch ductile aluminium alloys developed by us enable the construction of mobile pressure vessels such as silo vehicles or silo rail wagons made from aluminium.

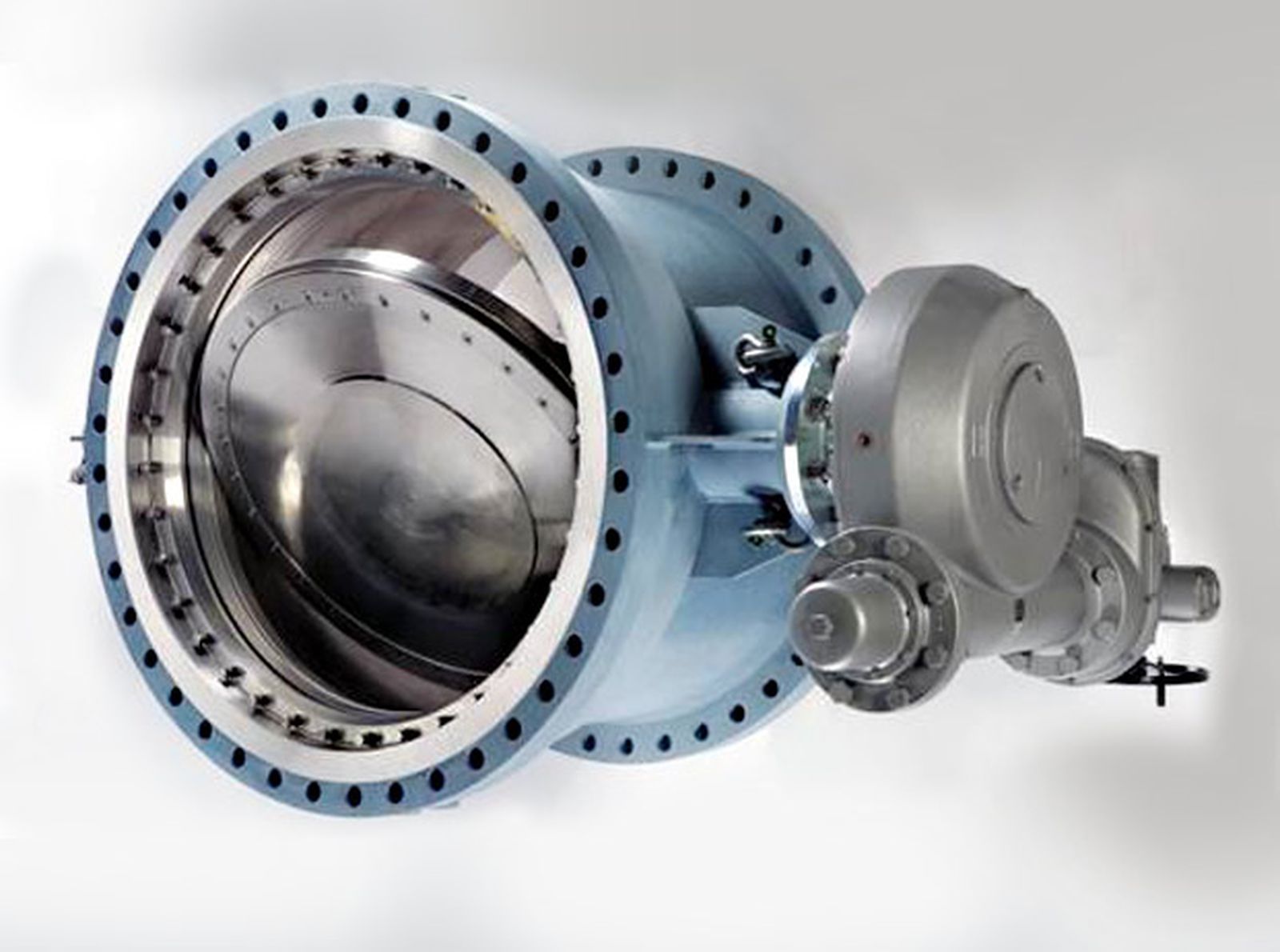

Closing flaps for valves

Closing flaps for valves

For gas equipment we supply closing flaps for valves made from ductile, high-tensile aluminium alloys. These lighter flaps enable the flaps to be closed faster or using less force, which in turn reduces energy consumption, purchase costs and operating costs.

Contact

Get in touch.

Get in touch.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.